Healthy Frosting vs a Refrigerant Starved Heat Pump

How to tell the difference between normal winter operation and frosting caused by refrigerant undercharge

What “Normal” Frosting Looks Like

Seeing frost or ice on a heat pump often triggers concern—but not all frosting is bad. In cold, damp weather, a healthy heat pump will build a layer of frost on the outdoor coil while it extracts heat from outdoor air.

Characteristics of healthy frosting

- Even, light frost across most or all of the coil face

- Frost develops gradually over time

- Frost clears fully during a defrost cycle

- Heat output resumes normally after defrost

Typical conditions where normal frosting happens

- Outdoor temperatures around +5°C down to −5°C (often worst in damp air)

- Fog, drizzle, or high humidity

- Long, steady run times

In other words: a light, even frosting pattern that clears itself is usually a sign the system is transferring heat as expected.

What Happens During a Normal Defrost

In snowy or freezing conditions, the heat pump will regularly enter defrost mode to prevent ice build-up and protect efficiency. This is normal.

During defrost you may notice

- The outdoor fan stops briefly

- Steam/vapour rising from the unit

- Clicking sounds as valves change over

- A short-lived reduction in heating output

After defrost, the coil should look mostly clear, with perhaps a little moisture remaining. Meltwater should drain away rather than freezing into a growing ice mound.

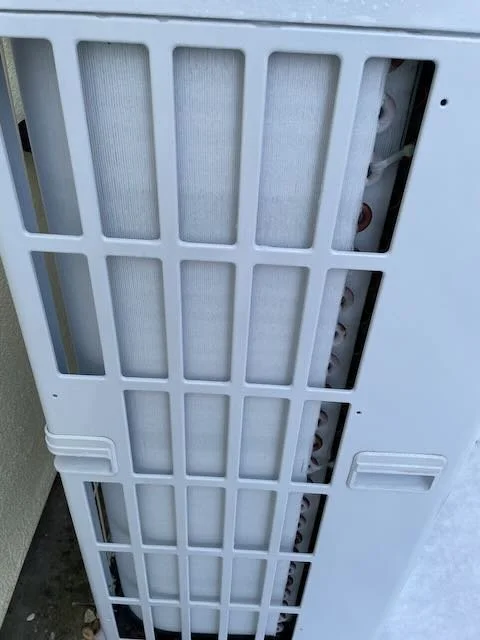

Frosting Caused by Refrigerant Undercharge

When refrigerant charge is low (often due to a leak), the system can’t distribute refrigerant evenly through the outdoor coil. The result is an abnormal frosting pattern that tends to get worse with time.

Key visual signs of undercharge

- Patchy frost, often starting in one corner or along one edge

- One section of the coil heavily iced while the rest looks unusually clear

- Frost/ice that does not fully clear during defrost

- Ice becomes thicker after each cycle

Why Undercharge Causes Abnormal Frosting

Refrigerant carries heat through the system. If there isn’t enough refrigerant, mass flow and distribution through the coil can become uneven. That can make only part of the coil reach the conditions where frost forms, while other sections don’t participate properly in heat exchange.

Over time, refrigerant undercharge can lead to reduced output, repeated fault codes, compressor stress, and eventual shutdown.

Healthy Frost vs Undercharge: Quick Comparison

| Feature | Healthy Frosting | Undercharge Frosting |

|---|---|---|

| Frost pattern | Even across coil | Patchy / localised |

| Clears during defrost | Yes, fully | No or only partially |

| Ice thickness | Light, powdery | Thick, hard ice |

| Heat output | Recovers after defrost | Continues to drop |

| Trend over days/weeks | Stable | Worsens progressively |

| Ambient temperature | Occurs when air < 5ºC | Can occur at anytime |

Simple Checks You Can Do Safely

Before assuming a refrigerant fault, rule out the basics. Some airflow and drainage problems can mimic undercharge symptoms.

- Is airflow clear (no snow, leaves, or debris blocking intake/exhaust)?

- Is the coil simply frosted evenly and waiting for a defrost?

- Is the condensate drain free and not freezing into an ice mound?

- Has the unit recently completed a defrost cycle?

When to Call an Engineer

It’s sensible to book an engineer if you see any of the following:

- Frost always forms in the same small area

- Defrost runs but ice remains on the coil

- Performance steadily worsens in similar weather

- Repeated fault codes that return soon after resets

- Don’t chip ice off the coil with tools

- Don’t pour hot water on the outdoor unit

- Don’t keep power-cycling and resetting faults repeatedly

- Don’t attempt any refrigerant-related DIY work

Key Takeaway

Healthy frosting is even, temporary, and self-clearing.

Undercharge frosting is patchy, persistent, and progressive.

If you’d like, I can turn this into a visual diagnostic card for your site (photo placeholders + captions) or add a short “engineer-only checks” section that covers superheat/subcool and common leak points.